NEC code junction box accessibility plays a crucial role in electrical safety and maintenance. This comprehensive guide explores the requirements, importance, methods, and enforcement aspects of junction box accessibility as per the National Electrical Code (NEC), providing a thorough understanding for professionals and homeowners alike.

The NEC establishes specific dimensions, clearances, and exceptions for accessible junction boxes, ensuring easy access for maintenance, troubleshooting, and safety inspections. By adhering to these guidelines, electrical systems can be designed and installed to meet code requirements and enhance overall safety.

National Electrical Code (NEC) Junction Box Accessibility Requirements

The National Electrical Code (NEC) sets forth specific requirements for the accessibility of junction boxes to ensure safe and efficient maintenance and inspection of electrical systems.

General Requirements

Junction boxes must be accessible without removing any permanent part of the building structure or finish. They must be located at least 12 inches (305 mm) from the floor and at least 6 inches (152 mm) from the ceiling. The minimum clear working space in front of the junction box must be 30 inches (762 mm) wide and 36 inches (914 mm) high.

Exceptions

There are a few exceptions to the general accessibility requirements. Junction boxes may be located less than 12 inches (305 mm) from the floor if they are installed in a raceway or if they are used for switches or receptacles.

Importance of Junction Box Accessibility

Ensuring junction box accessibility is crucial for electrical safety and maintenance.

Accessible junction boxes allow for easy inspection, troubleshooting, and repairs, reducing the risk of electrical accidents and ensuring the proper functioning of electrical systems.

Safety Considerations

Inaccessible junction boxes pose a safety hazard as they make it difficult to quickly access and isolate electrical circuits in the event of an emergency.

This can delay response times, potentially leading to more severe electrical incidents and increased risk of injury or damage to property.

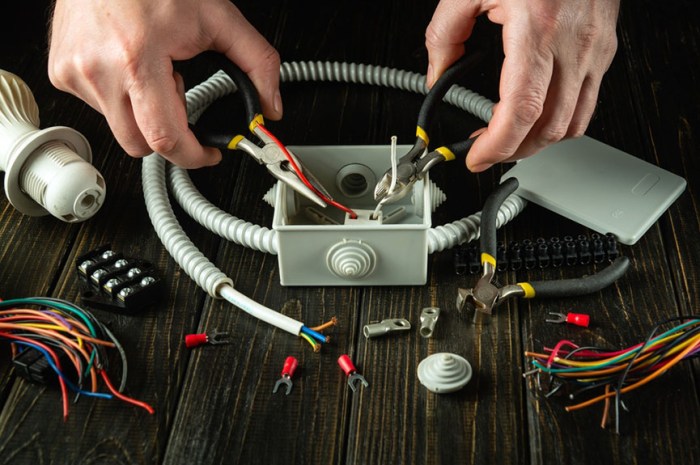

Maintenance and Troubleshooting

Accessible junction boxes facilitate regular maintenance and troubleshooting.

By providing easy access to electrical connections, technicians can quickly identify and resolve issues, minimizing downtime and ensuring the reliability of electrical systems.

Consequences of Inaccessible Junction Boxes

Inaccessible junction boxes can have severe consequences, including:

- Delayed response times to electrical emergencies

- Increased risk of electrical accidents

- Difficulty in troubleshooting and repairing electrical issues

- Reduced reliability of electrical systems

Methods to Ensure Junction Box Accessibility

Ensuring junction box accessibility is crucial for electrical safety and maintenance. Various methods can be employed to achieve this, depending on the location and accessibility requirements.

Recessed Junction Boxes

Recessed junction boxes are installed flush with the wall or ceiling surface, providing a discreet and space-saving solution. They are commonly used in finished areas where aesthetics are important. Recessed boxes require cutting into the wall or ceiling material, making them suitable for new installations or renovations.

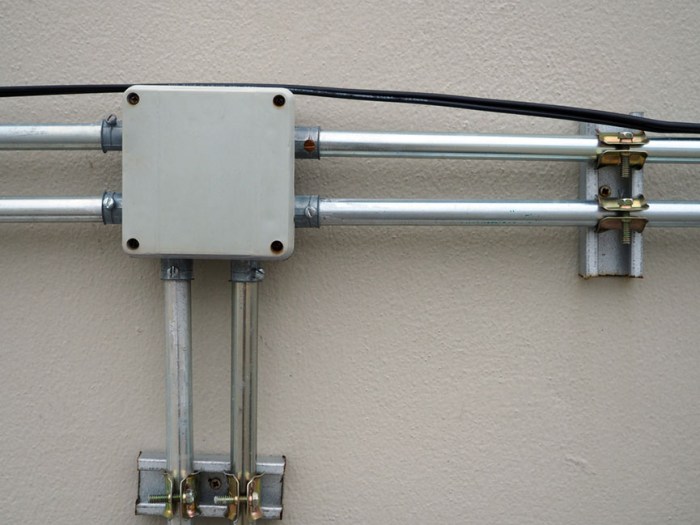

Surface-Mounted Junction Boxes, Nec code junction box accessibility

Surface-mounted junction boxes are installed on the surface of the wall or ceiling, providing easy access for maintenance and repairs. They are often used in unfinished areas, such as basements or attics, where aesthetics are less of a concern. Surface-mounted boxes are typically more accessible than recessed boxes.

Pull Boxes

Pull boxes are larger junction boxes that provide access to multiple cables or wires. They are often used in commercial and industrial applications where multiple circuits need to be connected or terminated. Pull boxes are typically surface-mounted and have removable covers for easy access.

Selection Considerations

When selecting the appropriate junction box type, consider the following factors:

- Location:Recessed boxes are suitable for finished areas, while surface-mounted boxes are more appropriate for unfinished areas.

- Accessibility:Surface-mounted boxes provide easier access for maintenance and repairs.

- Size:Pull boxes are necessary when multiple cables or wires need to be connected.

- Aesthetics:Recessed boxes offer a more discreet appearance, while surface-mounted boxes are more visible.

Accessibility Considerations for Specific Locations: Nec Code Junction Box Accessibility

The accessibility of junction boxes is particularly crucial in certain locations due to safety concerns and maintenance requirements. These locations include hazardous locations, wet locations, and confined spaces.

Hazardous Locations

In hazardous locations, where flammable or explosive gases, vapors, or dust are present, ensuring junction box accessibility is vital for safety. Junction boxes must be readily accessible for inspection and maintenance to prevent the accumulation of flammable materials and potential hazards.

Wet Locations

Junction boxes in wet locations, such as bathrooms, kitchens, and outdoor areas, are susceptible to moisture and water damage. Accessibility is essential for regular inspections and maintenance to prevent corrosion, electrical faults, and safety risks.

Confined Spaces

Junction boxes located in confined spaces, such as attics, crawlspaces, and narrow electrical panels, pose challenges for accessibility. Ensuring accessibility in these locations is crucial for maintenance, troubleshooting, and emergency situations.

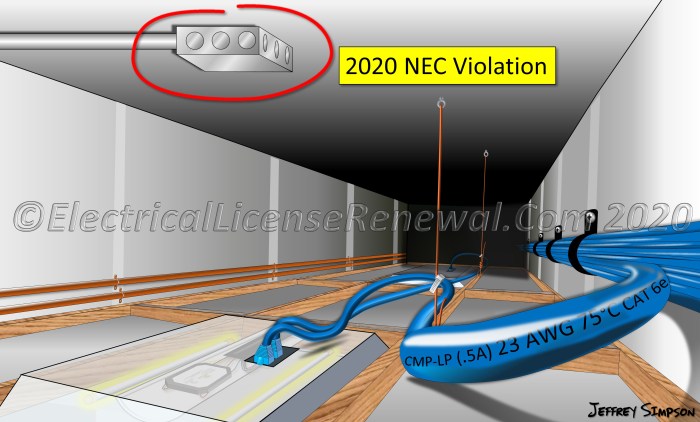

Inspection and Enforcement of Accessibility Requirements

Ensuring compliance with junction box accessibility requirements is crucial for maintaining electrical safety and accessibility in buildings. Electrical inspectors play a critical role in verifying that junction boxes are installed and maintained in accordance with the National Electrical Code (NEC) and other applicable regulations.

Inspection Procedures

Electrical inspectors conduct thorough inspections to verify junction box accessibility. They examine the location, size, and accessibility of junction boxes to ensure they meet the NEC requirements. Inspectors check for clear access to junction boxes, unobstructed by furniture, equipment, or other obstacles.

They also verify that junction boxes are properly labeled and identified for easy identification during maintenance or repairs.

Consequences of Non-Compliance

Non-compliance with junction box accessibility requirements can have serious consequences. Inaccessible junction boxes can hinder maintenance and repairs, increasing the risk of electrical hazards and safety concerns. Additionally, non-compliance can result in fines, penalties, or even legal action against the responsible parties.

FAQ Section

What are the general requirements for junction box accessibility as per NEC?

Junction boxes must be accessible without removing any part of the building structure or finish, and must be within reach of a person standing on the floor or a step stool.

Why is junction box accessibility important?

Accessible junction boxes facilitate maintenance, troubleshooting, and safety inspections, ensuring the safety and reliability of electrical systems.

What are some methods to ensure junction box accessibility?

Recessed junction boxes, surface-mounted junction boxes, and pull boxes can be used to ensure junction box accessibility in different scenarios, depending on location and accessibility requirements.