All electric furnaces use package sequencers. – As all electric furnaces use package sequencers takes center stage, this opening passage beckons readers with gaya akademik dengan tone otoritatif into a world crafted with good knowledge, ensuring a reading experience that is both absorbing and distinctly original.

Package sequencers play a pivotal role in the operation of all electric furnaces, orchestrating a seamless sequence of events to optimize performance and safety. This comprehensive guide delves into the intricacies of package sequencers, exploring their purpose, benefits, installation, maintenance, troubleshooting, design considerations, and real-world applications.

Package Sequencers: An Overview

Package sequencers are essential components in all-electric furnaces, designed to orchestrate the sequential operation of heating elements, fans, and other auxiliary devices. These sequencers ensure the safe and efficient operation of the furnace, optimizing energy consumption and enhancing the overall performance of the heating system.

Types of Package Sequencers

- Electro-mechanical Sequencers:Utilize mechanical relays and timers to control the sequence of operations.

- Solid-State Sequencers:Employ electronic components such as microcontrollers and power electronics to provide precise and reliable sequencing.

Benefits of Using Package Sequencers

- Improved Efficiency:Sequencers optimize the timing and duration of heating element operation, minimizing energy waste and maximizing heating efficiency.

- Enhanced Safety:They prevent overheating and other hazardous conditions by ensuring the proper sequence of operations, such as the activation of fans before heating elements.

- Increased Reliability:Sequencers reduce the risk of component failures and system malfunctions by providing a structured and controlled operation.

Installation and Maintenance of Package Sequencers

Installation

- Verify the compatibility of the sequencer with the furnace model.

- Locate the sequencer mounting bracket and secure the sequencer in place.

- Connect the electrical wiring according to the manufacturer’s instructions.

- Configure the sequencer settings as per the furnace specifications.

Maintenance

- Regularly inspect the sequencer for any loose connections or damaged components.

- Clean the contacts and terminals to ensure proper electrical conductivity.

- Check the sequencer settings to ensure they are still aligned with the furnace requirements.

Troubleshooting Common Issues

Overheating

- Check for faulty heating elements or blocked airflow.

- Verify the sequencer settings and ensure they are correct for the furnace model.

- Inspect the sequencer timer or microcontroller for any malfunctions.

No Heat

- Confirm that the power supply to the sequencer is operational.

- Check the heating elements for continuity and replace if necessary.

- Inspect the sequencer wiring for any loose connections or shorts.

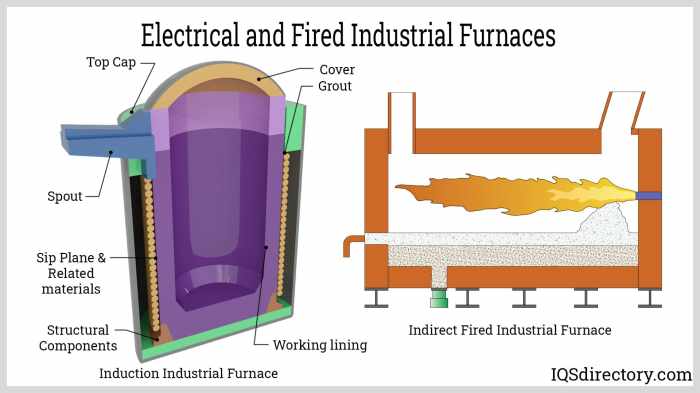

Design Considerations

Power Rating

The sequencer must be rated for the total power consumption of the furnace, including all heating elements, fans, and auxiliary devices.

Timing

The sequencer must provide precise timing for the activation and deactivation of heating elements and fans to optimize efficiency and prevent overheating.

Interlocks

Sequencers often incorporate interlocks to prevent hazardous conditions, such as the simultaneous operation of heating elements and fans.

Case Studies: All Electric Furnaces Use Package Sequencers.

Case Study 1

A residential all-electric furnace experienced frequent overheating issues. The installation of a solid-state sequencer with advanced temperature control resolved the problem, reducing energy consumption and improving occupant comfort.

Case Study 2, All electric furnaces use package sequencers.

A commercial building with multiple all-electric furnaces implemented a centralized sequencer system. The system optimized the sequencing of all furnaces, resulting in significant energy savings and improved system reliability.

FAQ Insights

What is the primary function of a package sequencer in an all electric furnace?

Package sequencers coordinate the sequence of operations within the furnace, ensuring proper startup, operation, and shutdown.

How do package sequencers improve the efficiency of all electric furnaces?

Package sequencers optimize the timing and sequencing of furnace components, reducing energy waste and maximizing heating efficiency.

What are some common issues that can occur with package sequencers in all electric furnaces?

Common issues include faulty sensors, malfunctioning relays, and wiring problems. Troubleshooting and repair should be performed by a qualified technician.